go to zeenea.com

.png?width=700&height=323&name=Group%2088%20(2).png)

Fortune Business Insights stated that “The global big data in manufacturing industry size stood at USD 3.22 billion in 2018 and is projected to reach USD 9.11 billion by 2026, exhibiting a CAGR of 14.0% during the forecast period.”

However, manufacturing industries are still struggling to put in place a data-driven strategy, facing challenges such as the difficulty to recover investments and drive innovation at a large scale, in order to respond to the changes in business models, or decrease customer churn rates.

To face those kinds of challenges and changes, becoming data-driven is a matter of survival.

With the rising adoption of interconnected environments, supply chain management in manufacturing operations is becoming more complex. To optimize supply chain operations, there is a need to examine the process at a granular level.

Data supports manufacturers in understanding the processes and errors associated with it.

With predictive maintenance, supervisors schedule downtime at regular intervals to repair assets before an unexpected breakdown leads to costly unplanned downtime.For manufacturers that track these variables, data analysis can help determine root causes and identify factors that lead to errors.

By enabling this end-to-end data collection on information assets, manufacturers can react quickly to unexpected events, provide accurate and timely reporting and documentation to meet industry regulations and quality audits, increase customer service levels with timely and accurate order information, and so much more.

With the arrival of big data technologies, compliance and quality management systems target data itself in addition to manufacturers' processes. It is therefore important to have solutions put in place to make sure industries comply with data regulations such as the GDPR.

By collecting and audit-trailing manufacturing data, manufacturing companies can better track production processes and collect exponential amounts of data in order to innovate on new or current customer services & products.

- Jean-Pierre Huchet, Head of Renault’s Data Lake

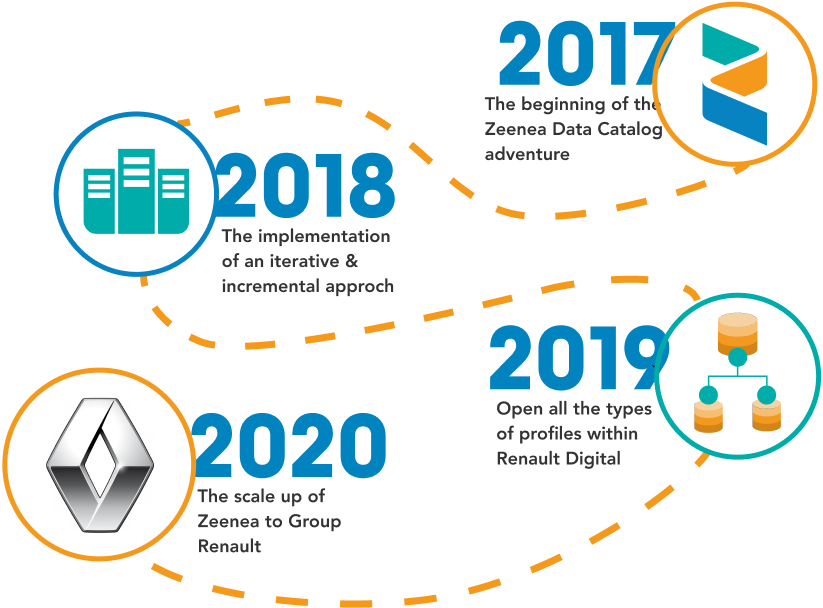

In 2017, Renault Digital was born with the aim of transforming the Renault Group into a data-driven company. In a conference in Zeenea’s Data Centric Exchange (French), Jean-Pierre Huchet, Head of Renault’s Data Lake, states that their main data challenges were:

By choosing Zeenea Data Catalog as their data catalog software, they were able to overcome these challenges and more. Zeenea today has become an essential brick in Renault Digital's data projects.

From a manufacturing point of view, IoT is a way to digitize industry processes. Industrial IoT employs a network of sensors to collect critical production data and uses various software to turn this data into valuable insights about the efficiency of the manufacturing operations.

Total has recently opened their Digital Factory earlier this year in Paris. The Digital Factory will bring together up to 300 different profiles such as developers, data scientists and other digital experts to accelerate the Group’s digital transformation.

At Zeenea, we define a data catalog to be “A detailed inventory of all data assets in an organization and their metadata, designed to help data professionals quickly find the most appropriate data for any analytical business purpose.”

Our universal connectivity and API-first approach allows Zeenea to adapt to any system, and to any data strategy (edge, cloud, multi-cloud, cross-cloud, hybrid) to build an enterprise-wide information repository. See all of our connectors

A data catalog built for manufacturing industries must have:

Our data catalog automates data lineage by gathering data processes and data assets transformations from ETL platforms and data pipelines, or from manual descriptions for compliance and regulation. Zeenea also provides an audit trail for any action done in the data catalog.

A data catalog is for everyone! Data shouldn’t be kept away and only used by a certain group of people or single individuals. A data catalog is for any user working with their enterprise data.

Zeenea’s pricing strategy enables any organization to start small and scale fast by adopting an agile, incremental, and pragmatic data governance initiatives. Our data catalog’s agile design enables companies to launch bottom-up data driven initiatives to maximize ROI in a matter of weeks.

Contact : Paris, France : +33(0)1-73-30-69-91 | Mail : info@zeenea.com